Highlights

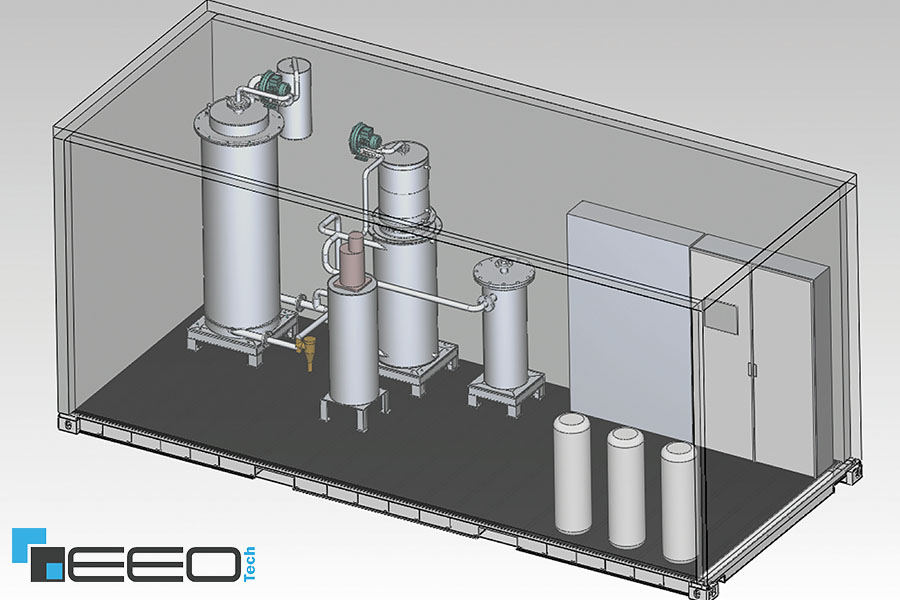

The GTE separates liquid manure and digestate into valuable raw products.

Due to the low energy consumption and prevention of residual waste disposal the plant has a valuable ecological and environmental impact.

| TGT | Thermal Separator | Roughly separates the solid and liquid fractions |

| TTE | low temperature pyrolysis plant | Solids are converted into biochar |

| TAR | Thermal afterburning unit for exhaust gas | Cleans the exhaust gas at high temperatures through combustion |

| TNH | Separator NH3 | Separates approx. 90% of the ammonia |

| TUM | Distiller | separates pure water from the liquid ferment material |